The Power of Diesel Generators for Marine Use

Introduction

In the vast expanse of the open seas, ships rely on a variety of systems to ensure smooth sailing and operational efficiency. One critical component that plays a vital role in the functioning of marine vessels is the diesel generator. These powerful machines provide the necessary electrical power to run essential equipment onboard, making them indispensable for the maritime industry. In this article, we will explore the significance of diesel generators for marine use, their working principles, advantages, maintenance requirements, and the latest technological advancements in this field.

Importance of Diesel Generators in Marine Applications

Diesel generators are the backbone of electrical power generation on marine vessels, serving as a reliable source of energy to meet the diverse needs of modern ships. Whether it's powering propulsion systems, navigation equipment, communication devices, lighting, refrigeration units, or other onboard systems, diesel generators play a crucial role in ensuring the safety, comfort, and operational capabilities of the vessel.

Unlike shore-based power sources, ships operate in remote locations and challenging environments, making them heavily dependent on self-sustained power generation systems. Diesel generators offer the advantage of being compact, robust, and capable of delivering high power outputs, making them ideal for maritime applications where space is limited, and reliability is paramount.

Working Principles of Diesel Generators for Marine Use

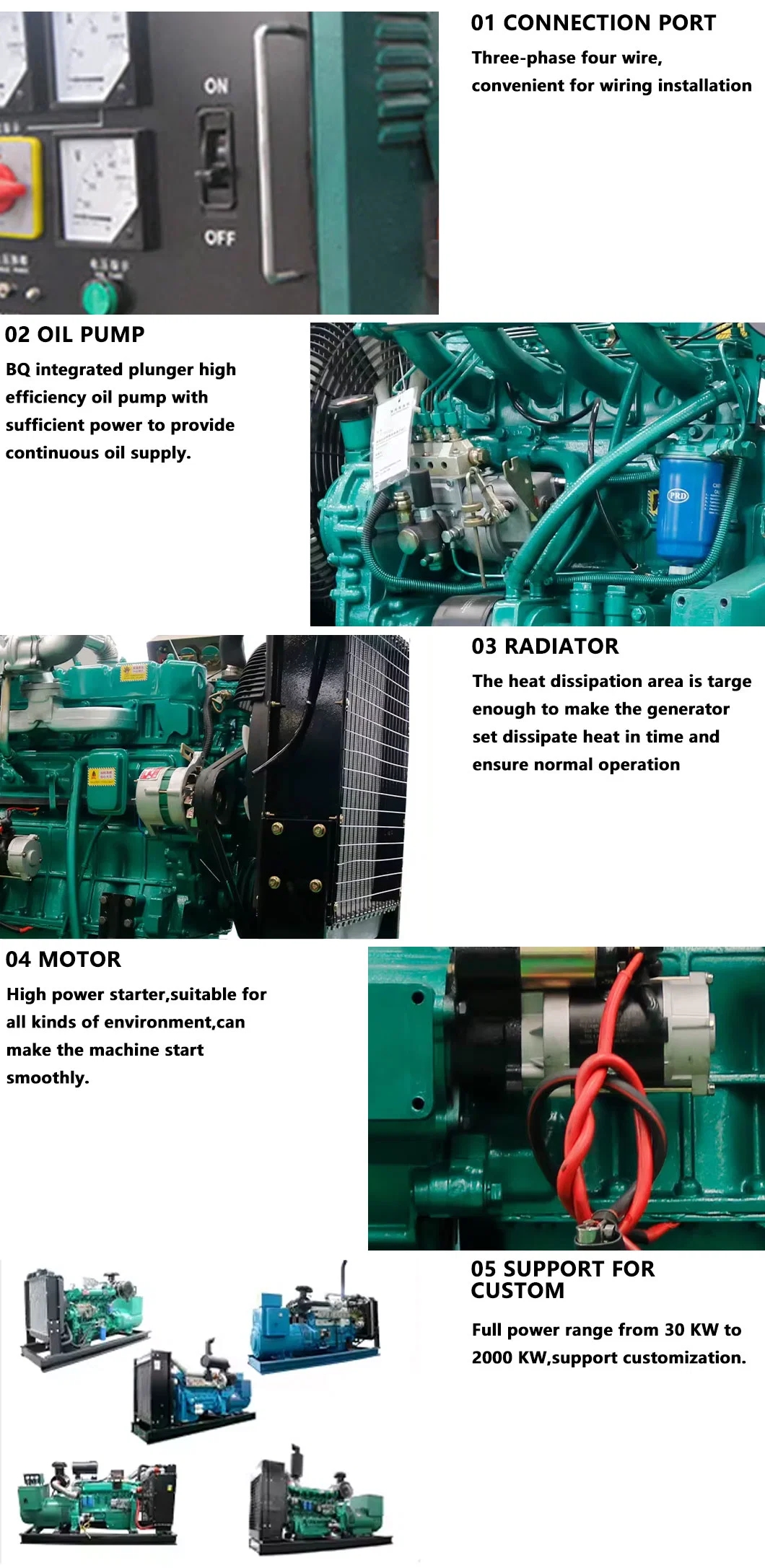

Diesel generators operate on the principle of converting the chemical energy stored in diesel fuel into mechanical energy through combustion. This mechanical energy is then transformed into electrical energy using an alternator or generator. The key components of a marine diesel generator include the engine, alternator, cooling system, fuel system, exhaust system, and control panel.

The process begins with the injection of diesel fuel into the combustion chamber of the engine, where it mixes with compressed air. The heat generated by the compression ignites the fuel, causing it to burn and release energy in the form of expanding gases. This energy drives the pistons in the engine, converting it into rotational motion that drives the alternator to produce electricity.

Advantages of Diesel Generators for Marine Use

Diesel generators offer several advantages that make them the preferred choice for marine applications:

1. Reliability: Diesel generators are known for their robustness and reliability, making them well-suited for the demanding conditions at sea. They can operate continuously for extended periods without compromising performance, ensuring a stable power supply onboard.

2. 400kw diesel generator : Diesel engines are more fuel-efficient compared to gasoline engines, allowing ships to maximize their range and operational capabilities without frequent refueling stops. This efficiency is crucial for long voyages and missions that require sustained power generation.

3. High Power Output: Diesel generators are capable of delivering high power outputs, making them suitable for powering a wide range of electrical equipment onboard, including propulsion systems, refrigeration units, and communication devices.

4. Durability: Marine diesel generators are designed to withstand harsh marine environments, including exposure to saltwater, humidity, and vibrations. Their robust construction and corrosion-resistant materials ensure long-term durability and performance.

5. Easy Maintenance: Diesel generators are relatively simple to maintain, with routine checks and servicing prolonging their operational lifespan. Spare parts are readily available, and servicing can be carried out onboard by trained personnel, minimizing downtime and maintenance costs.

Maintenance Requirements for Diesel Generators in Marine Applications

Proper maintenance is essential to ensure the reliable operation of diesel generators on marine vessels. Regular inspections, servicing, and repair work help prevent breakdowns, extend the lifespan of the equipment, and ensure optimal performance. Some key maintenance requirements for diesel generators in marine applications include:

1. Regular Inspections: Conduct routine visual inspections of the generator components, including the engine, alternator, cooling system, fuel system, and exhaust system. Check for signs of wear, leaks, corrosion, or damage that may affect performance.

2. Oil and Filter Changes: Replace the engine oil and filters at recommended intervals to ensure proper lubrication and prevent contaminants from damaging the engine components. Use high-quality lubricants suitable for marine diesel engines.

3. Cooling System Maintenance: Keep the cooling system clean and free from debris to prevent overheating. Check coolant levels, hoses, and radiator for leaks or blockages that may hinder proper cooling.

4. Fuel System Checks: Monitor fuel quality, tank levels, filters, and injectors to ensure a clean and uninterrupted fuel supply to the engine. Contaminated fuel can lead to engine damage and reduced performance.

5. Electrical System Inspections: Test the electrical connections, wiring, and control panel for loose connections, corrosion, or damaged components. Ensure proper grounding and insulation to prevent electrical faults.

6. Emission Control: Comply with environmental regulations by maintaining the exhaust system and emission control devices in good working condition. Regularly inspect and clean the exhaust manifold, muffler, and catalytic converter to reduce emissions.

Technological Advancements in Diesel Generators for Marine Use

Advancements in technology have led to the development of more efficient, reliable, and environmentally friendly diesel generators for marine applications. Some of the latest innovations in this field include:

1. Electronic Engine Control Systems: Modern diesel generators feature advanced electronic engine control systems that optimize fuel consumption, performance, and emissions. These systems monitor and adjust engine parameters in real-time to maximize efficiency and reduce environmental impact.

2. Variable Speed Generators: Variable speed generators adjust the engine speed according to the electrical load demand, resulting in improved fuel efficiency and reduced noise levels. These generators are ideal for ships with fluctuating power requirements.

3. Hybrid Power Systems: Hybrid power systems combine diesel generators with energy storage solutions, such as batteries or supercapacitors, to enhance efficiency and reduce emissions. These systems allow for better load management and utilize renewable energy sources to supplement diesel power generation.

4. Remote Monitoring and Diagnostics: Remote monitoring systems enable real-time monitoring of diesel generator performance, fuel consumption, and maintenance needs from shore-based locations. This proactive approach to maintenance helps prevent downtime and optimize operational efficiency.

5. Exhaust Gas Aftertreatment: Advanced exhaust gas aftertreatment technologies, such as selective catalytic reduction (SCR) and diesel particulate filters (DPF), help reduce harmful emissions from diesel generators. These systems ensure compliance with stringent environmental regulations and promote cleaner air quality.

Conclusion

Diesel generators are indispensable power sources for marine vessels, providing the electrical energy needed to run essential equipment onboard and ensure operational efficiency at sea. Their reliability, fuel efficiency, high power output, durability, and ease of maintenance make them the preferred choice for maritime applications. With continuous technological advancements improving their performance, efficiency, and environmental impact, diesel generators remain at the forefront of power generation solutions for the marine industry. By understanding the working principles, advantages, maintenance requirements, and latest innovations in diesel generators, ship operators can optimize their power generation capabilities and navigate the challenges of the open seas with confidence.